Maximilian Dammann

Engler-Bunte-Institut, EBI ceb

Chemische Energieträger – BrennstofftechnologieEngler-Bunte-Ring 1

76131 Karlsruhe

Numerical Modelling and Simulation of High Temperature Processes

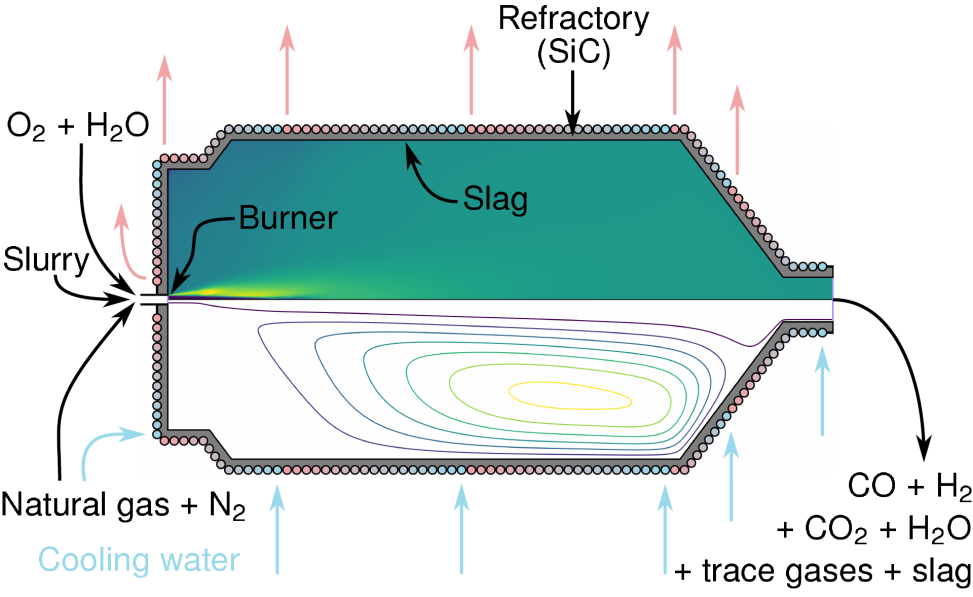

The Research on numerical modelling and simulation has become an important element for developing of validated models and for the design and the scale-up of reactors. In collaboration with the Institute for Technical Chemistry (ITC vgt) at Karlsruhe Institute for Technology and the Institute for Energy Process Engineering and Fuel Technology (IEVB) at Clausthal University of Technology, in particular, we are investigating and improving the description of sub-processes in entrained flow gasification :

- vaporisation of liquid biomass fuels,

- decomposition and heterogeneous gasification of both liquid and solid biomass fuels,

- homogeneous gasification,

- radiation,

- slagging.

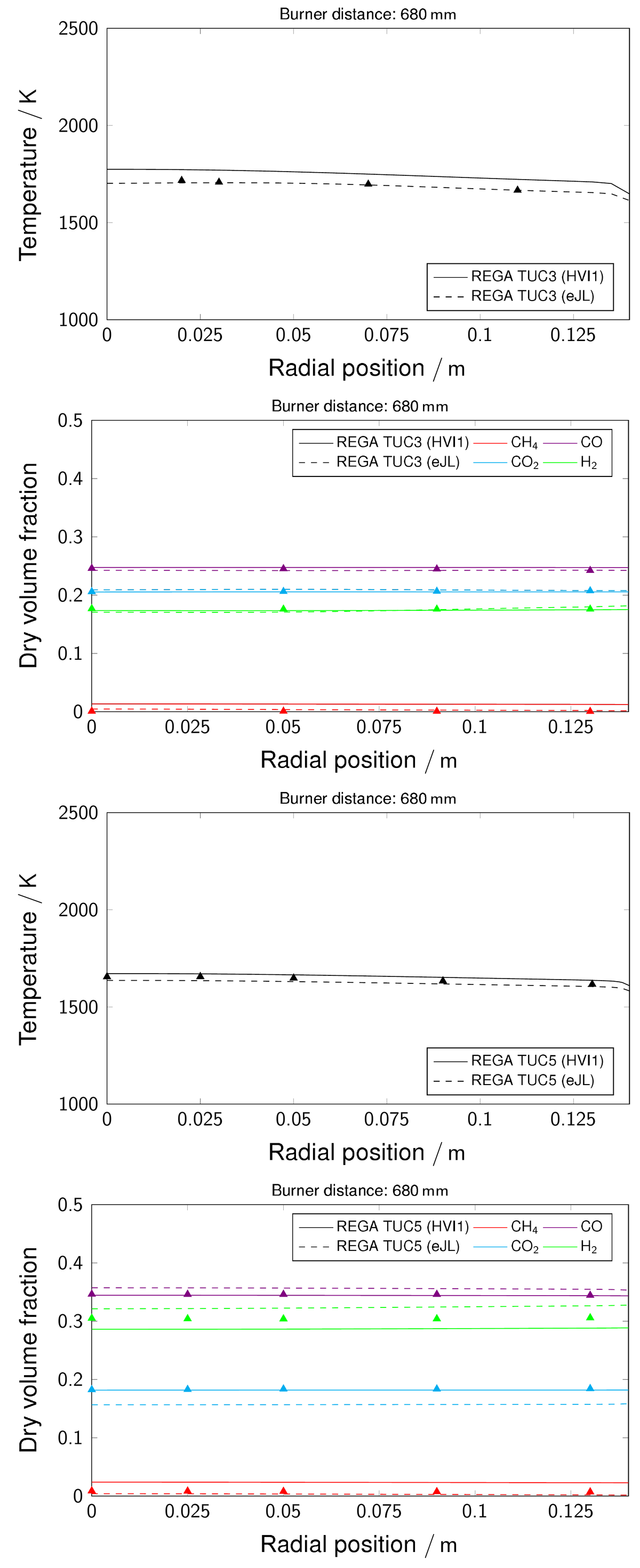

Using numerical models of an atmospheric entrained flow gasifier (REGA) and of a high-pressurised entrained flow gasifier (bioliq EFG), we are testing and validating new models for entrained flow gasification of biomass fuels.

Research topics

- Numerical modelling and simulation of gasification processes in entrained flow gasifiers

- Numerical modelling and simulation of steady-state and transient slagging

- Numerical modelling and simulation of radiation using LBL, WSGGM and Mie theory

- Numerical modelling and simulation of heterogeneous gasification reactions

- Numerical modelling and simulation of combustion processes in high pressure combustion chambers using hydrogen