Catalytic Fuel Conversion

The production and conversion of chemical energy carriers is often carried out by catalytic processes. In the case of renewables, this can be applied in particular to the biomass gasification route with its subsequent catalytic synthesis processes, e.g. SNG synthesis.

The numerous process requirements depend on both the raw materials and the desired products. Therefore, in many cases, new process concepts, e. g. dynamically operable catalytic reaction units with a high level of process integration, have to be developed.

R&D-work at EBI-ceb focusses primarily on the appropriate concepts and the fundamental theoretical and experimental issues that arise concerning process layout and design.

Physico-chemical Fuel Processing

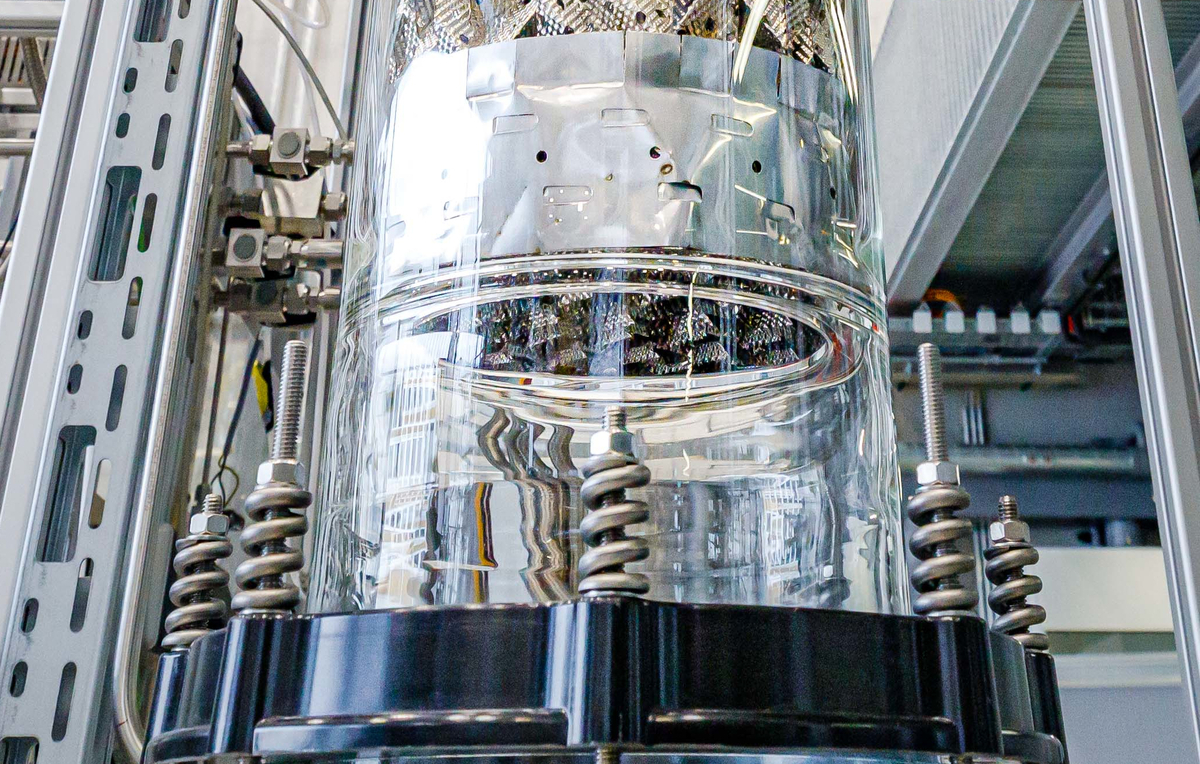

Chemical fuels for technical processes have to meet strict standards with respect to purity and fuel composition. In order to meet these specifications, energy-efficient purification technologies are needed. In some cases, fuel purification processes can also be beneficially integrated into the actual fuel production or conversion steps.

At EBI-ceb, new concepts for the processing of fuels (mainly gaseous) are developed by experimental and modelling work and evaluated in terms of optimization of established processes or development of new processes.

Thermochemical Fuel Conversion

The energetically and ecologically efficient use of both biogenic and fossil energy resources in energy conversion processes with high efficiencies, wide ranges of fuels, as well as large load and product flexibility is possible through the thermochemical processing of fuel. At EBI-ceb the basics of pyrolysis and gasification of solid and liquid fuels are developed based on experimental data and process modelling. One of the main focal points is the gasification of biomass based fuel suspensions under entrained flow conditions at high pressures.

Chemical Conversion of Renewable Energies

Against the background of the change in the energy system conversion technologies for renewable energies become more and more important. Especially the transport sector has need for action, as this sector has typically in most countries the largest share in the end energy consumption, but also the lowest share of renewables. Over chemical conversion processes, like Fischer Tropsch synthesis or the synthesis of mixed alcohols, fuels with high quality can be produced from biomass or also from CO2 and renewable hydrogen (produced from excess electricity).

At EBI ceb these synthesis are investigated experimentally and are also modelled. The R&D is one the one side fundamental, but also applied R&D is done. The work focuses on the optimisation of the reaction itself, where different types of reactors are used (fixed bed, slurry), but also on the whole system. The focus of work is here the transient operation of the sythesis. With the cooperation with BEST there is also the possibility to have access to pilot plants. Another topic of R&D is the upgrading of the raw products, which is mainly done by hydroprocessing. Aim of the work is to convert the FT products in sellable chemicals of in kerosene.